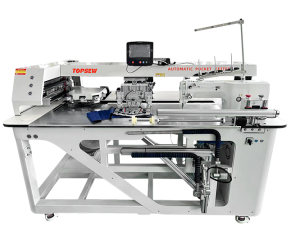

Automatic Kangroo Pocket Setting Machine TS-199-6730

1. High efficiency: 6-8 pockets/ minute. Comparison: Need 3 to 5 years working experience on sewing for pocket making, 4 to 6 workers on one production line, and need a lot of workers to prepare for other jobs such as make lines, ironing etc on traditional process; One person can operate 2 machines Using this machine can save 8 to 10 workers for factory.

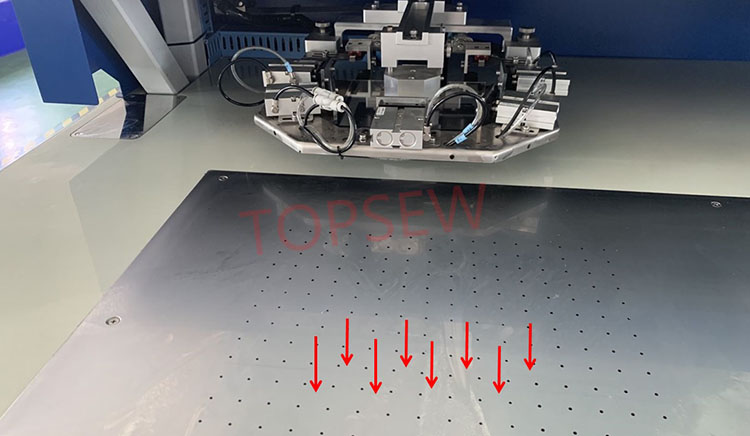

2. Kangroo Automatic Pocket Setter Machine with extra large area and equipped with suction fan, makes fabric smooth on the ironing free working position effectively to stitch.

3. Stainless steel operation table effectively ensures cleanness of the pockets during sewing. Three steps are completed on the same operation table. The stitch is very accurate and beautiful.

4. Equipped with suction fan, makes fabric smooth on the ironing free working position effectively to stitch.

5. When the machine is working, only need one person to put the material. Ironing free, automatic folding pocket, stitching, bar tacking, trimming and collecting all these processes finished by the machine automatically not only to provide the factories high- tech assurance to save the production process cost but also provide the production ability to get more orders.

6. Control system independent. Any patterns can be made within sewing scope and also can add to program function of

stop at any point to add the pocket badge.

7. No need pay much to buy pocket ironing machine because of ironing free function; No need change the pocket folding clamps frequently, the clamp knives can be adjusted according to the size of pocket pieces, which save much cost on clamps making and increase the added value of using the machine for many factories. The cost of clamp is very low.

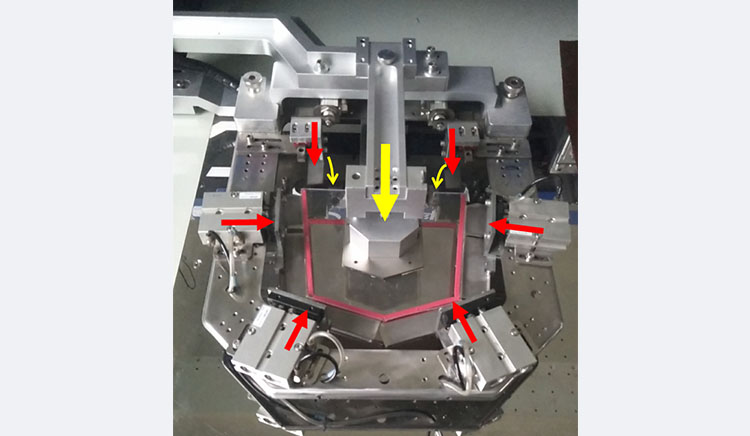

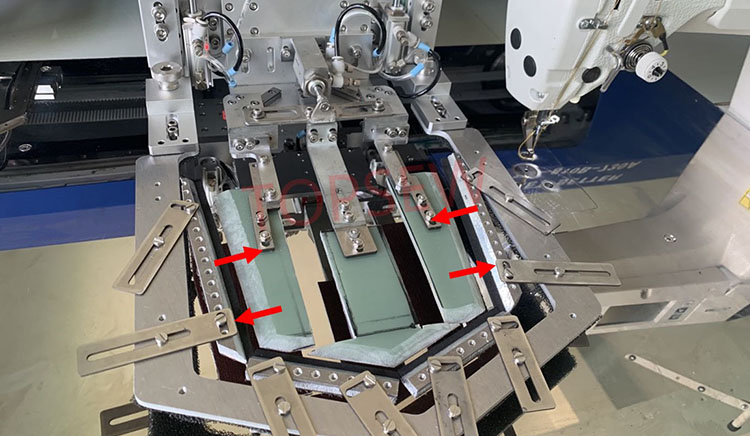

8. Automatic border double folding tool and free ironing start working at the same time, effectiveIy to fold the border, make the pocket shape perfect.

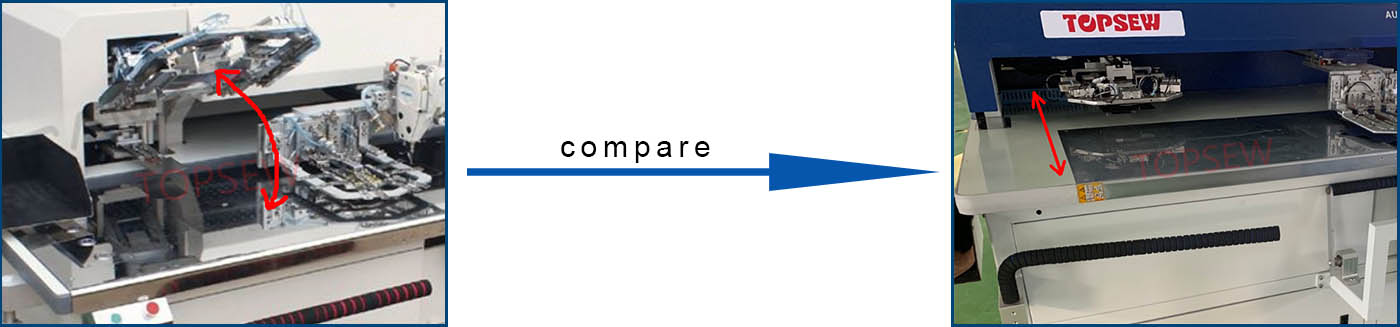

9. Folding frame is with latest technology front and back movement, and it is safer for operator.

10. All servo motor driving. The machine head is Typical 6730

11. Four folding clamps can realize Square, Round, Pentagon etc.

12. Using direct drive servo motor for material feeding in X and Y direction. More stable and precise operation. Feeding speed is adjustable

13. Adjustable internal clamps foot can control sewing performance, increase working stability, provide beautiful stitching. Ensures perfect consistency and performance of all sewing job.

14. Initially adopts double cross" infrared precisely locates the materials in pocket feeding system. The location is obvious. Operation is very easy. Infrared location device is flexible. It can be adjusted according to different material shapes.

15. Flexible inter clamp is suitable for fixing the sewing sample to start smooth sewing.

16. Direct drive servo motor works stable, accurate sending and receiving signal which realizes receiving the order synchronously.

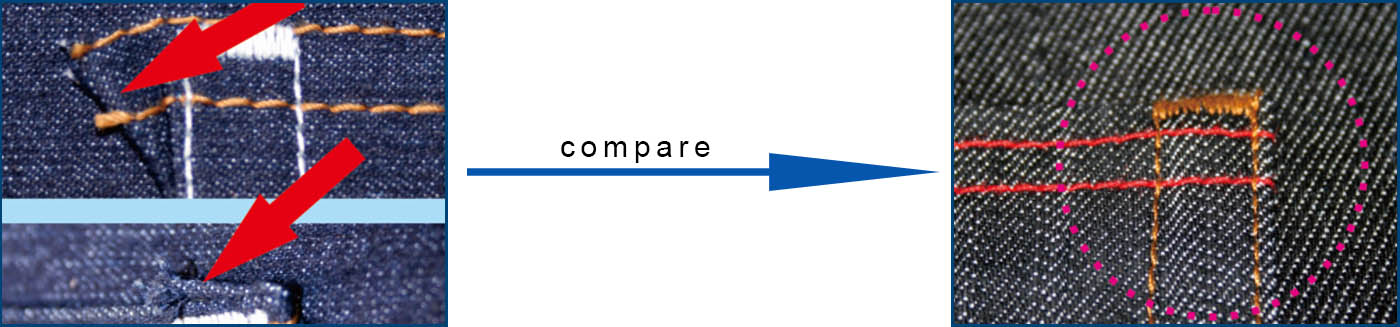

17. Effectively to solve missing stitch, excess stitch and askew stitch.

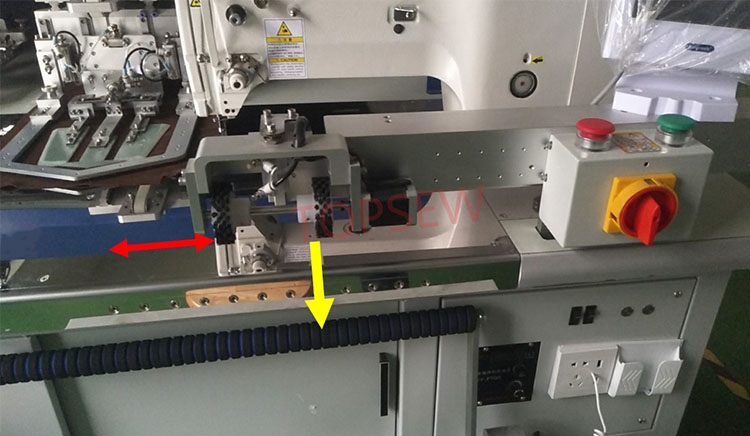

18. Side slip material collecting clamp automatically to work position to collect the material as soon as finish the previous sewing. Sideslip collecting the material smoothly and easily on the stainless steel table.

Without automatic edge double folding device

With automatic edge double folding device

Old folding clamp system

New folding clamp system

Old folding clamp system: up and down movement. New folding clamp system with latest technology front and back movement, and it is safe for operators.

Automatic Pocket Setting Machine with 6730 is suitable for any kind of exterior big pockets, focusing on jeans, shirts, casual pants, military trousers and work clothes and other similar sewing products.

| Highest sewing speed | 3500rpm |

| Machine needle | DP*17-DP*5 |

| Sewing stitch programming | Input mode of operation screen |

| Line programming storage capacity | Up to 999 kinds of patterns can be stored |

| Stitch distance | 1.0mm-3.5mm |

| Pressure foot rising height | 23mm |

| Sewing pocket range | X direction 50mm-400mm Y direction 50mm-450mm |

| Speed of sewing pockets | 6-8 pockets per minute |

| Folding method | Double cylinder folder in 7 directions works simultaneously to fold bags |

| Sewing methods | Bag folding and sewing are carried out at the same time, with protective function of broken thread |

| Pneumatic element | AirTAC |

| Feeding drive mode | DELTA servo motor drive (750w) |

| Power supply | AC220V |

| Air pressure and air pressure consumption | 0.5Mpa 22dm3/min |

| Weight | 650Kg |