In the fast-paced world of fashion and textile manufacturing, efficiency, precision, and innovation are the cornerstones of success. Garment factories around the globe are constantly seeking industrial sewing machine solutions that can reduce costs, boost productivity, and adapt to the ever-changing demands of the fashion industry. For six years, our automated sewing equipment factory has been at the forefront of this transformation, dedicated to redefining the standards of pocket-making technology with our cutting-edge Automatic Welt Pocket Machine, Fully Automatic Pocket Opening Machine, and a range of specialized textile machinery designed to empower garment factories worldwide.

What began as a vision to simplify and enhance the pocket-making process has evolved into a legacy of technical excellence. Over the past six years, we have poured our expertise, resources, and passion into perfecting our core product line—from the first prototype of our Automatic Welt Pocket Machine to the revolutionary, industry-changing innovation we are proud to introduce today. This journey has been driven by a single mission: to solve the most pressing pain points of garment factories, eliminate inefficiencies, and deliver industrial sewing machine solutions that truly live up to the promise of automation. Today, we stand as pioneers, bringing to the global fashion and textile market the world’s first, China’s first, mold-free automatic pocket machine—a breakthrough that disrupts traditional design concepts and ushers in a new era of fully automated, intelligent pocket production.

Six Years of Innovation: From Inception to Industry Leadership

Six years ago, we recognized a critical gap in the garment manufacturing equipment market. While the fashion industry was rapidly evolving, with faster production cycles and increasing demand for customization, the pocket-making process remained stagnant, relying on outdated technology that was slow, costly, and inflexible. Garment factories were struggling with traditional industrial sewing machines that required constant mold changes for different pocket sizes, a process that wasted valuable time, increased operational costs, and limited their ability to adapt to the dynamic needs of the fashion market.

Determined to address this challenge, we launched our research and development (R&D) initiative to create an Automatic Welt Pocket Machine that would redefine efficiency and versatility. Our team of engineers, textile experts, and industry specialists worked tirelessly, conducting hundreds of tests, refining designs, and integrating the latest technological advancements to ensure our machine was not just functional, but reliable, durable, and easy to use. In the early days, we faced countless obstacles—from optimizing the sewing mechanism to ensuring consistent precision across different fabric types—but our commitment to innovation never wavered.

Year after year, we made incremental improvements, listening closely to feedback from garment factory owners and operators worldwide. We enhanced the stability of our Automatic Welt Pocket Machine, improved its sewing speed, and expanded its compatibility with various textile materials—from lightweight cotton and silk to heavy denim and canvas, a critical feature for a market that serves diverse fashion segments. We also developed complementary models, including the automatic laser pocket welting machine, which leverages laser technology for unparalleled precision in pocket cutting and welting, and the automatic welt pocket with zipper, designed to streamline the production of zippered pockets for jackets, pants, and bags.

By the fifth year of our journey, our Automatic Welt Pocket Machine had become a trusted choice for garment factories across Asia, Europe, Africa, and the Americas. Clients praised its reliability, efficiency, and ability to produce high-quality pockets consistently—key factors in an industry where quality control is non-negotiable. Our back pocket machine, specifically designed for jeans and casual wear, also gained widespread acclaim, offering fast, precise stitching for one of the most iconic elements of modern fashion.

But we knew we could do more. The fashion industry was shifting toward greater customization, with small-batch orders becoming increasingly common. Garment factories needed an industrial sewing machine that could handle frequent size changes without the hassle and cost of mold replacements. This insight inspired our most ambitious R&D project yet—a revolutionary redesign of our core Automatic Welt Pocket Machine that would eliminate the need for mold changes entirely, setting a new standard for fully automatic pocket production.

A Revolutionary Breakthrough: The World’s First Mold-Free Fully Automatic Pocket Opening Machine

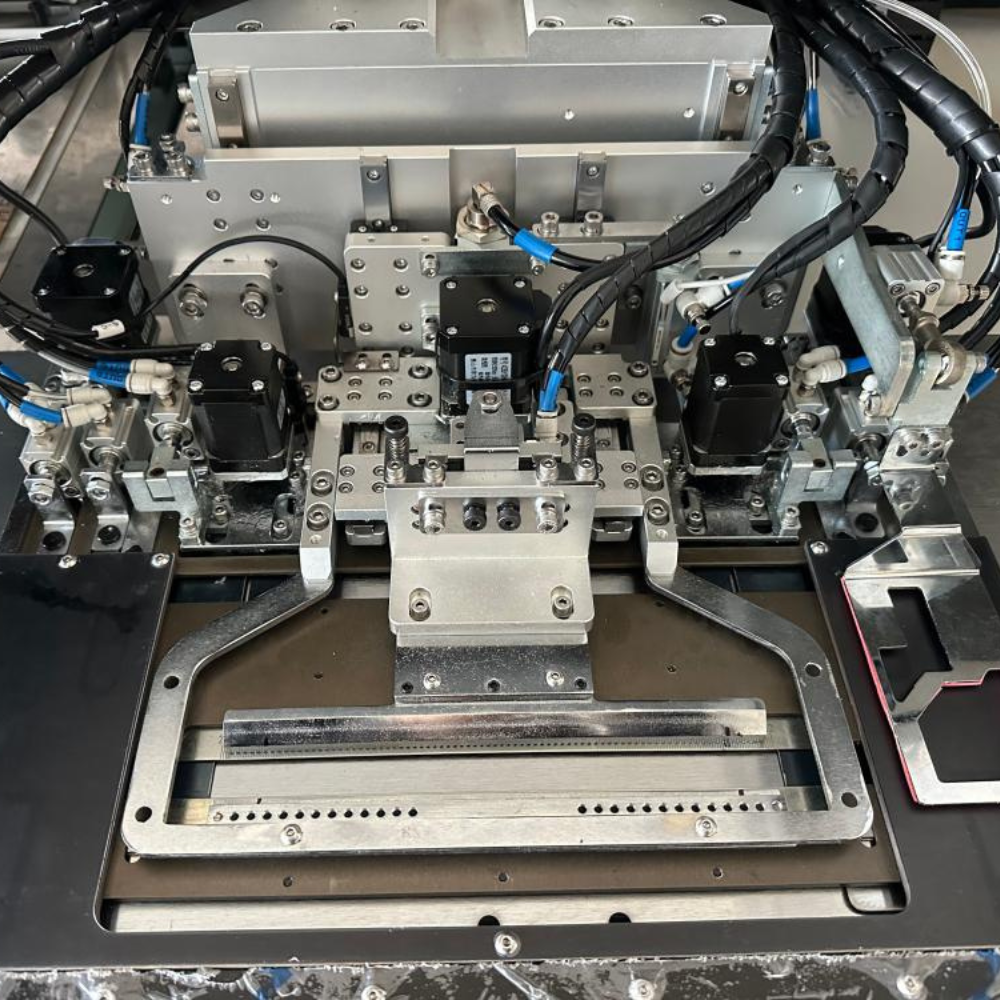

After more than a year of intensive R&D, countless hours of testing, and rigorous quality assurance checks, we are thrilled to introduce the world’s first, China’s first, mold-free Fully Automatic Pocket Opening Machine—a innovation that disrupts traditional design concepts and delivers true fully automatic functionality. This groundbreaking machine builds on our six years of expertise in automatic sewing technology, taking the efficiency, versatility, and intelligence of our Automatic Welt Pocket Machine to unprecedented heights.

To understand the significance of this breakthrough, it’s essential to recognize the pain points that have plagued garment factories for decades. For any garment factory producing pockets—whether for jeans, jackets, shirts, dresses, or bags—changing pocket sizes has always required changing molds. Each mold is custom-made for a specific size, meaning garment factories must invest heavily in a large inventory of molds to accommodate different designs. This not only increases upfront costs but also leads to ongoing expenses, as molds wear out over time and need to be replaced. Additionally, changing molds is a time-consuming process: workers must stop production, remove the old mold, install the new one, and calibrate the machine—often taking 30 minutes or more per change. In a fast-paced garment factory, where every minute counts, this downtime translates to lost productivity, missed deadlines, and reduced profitability.

Our revolutionary mold-free design eliminates these pain points entirely. We have reimagined the core mechanism of our Automatic Welt Pocket Machine, replacing the traditional mold-dependent system with a motor-controlled adjustable mechanism. Every component that affects pocket size—from the cutting blade to the sewing guide—is now controlled by high-precision motors, which can be calibrated in real time to match any desired pocket size. This means that when your garment factory needs to switch from one pocket size to another, there’s no need to change molds, no need to stop production for extended periods, and no need to invest in expensive mold inventories.

The process is simple, intuitive, and fast. Operators simply input the desired pocket dimensions (length, width, and depth) into the machine’s user-friendly touchscreen interface. Within seconds, the motors automatically adjust the components to the exact specifications, and the machine is ready to start production. Whether you need a small pocket for a children’s shirt, a medium pocket for a dress, or a large pocket for a jacket or pair of jeans, our Fully Automatic Pocket Opening Machine can adapt instantly—no tools, no mold changes, no downtime. This innovation is not just a convenience; it’s a game-changer for garment factories looking to reduce costs, boost productivity, and stay ahead in the competitive fashion and textile industry.

Unmatched Benefits: How Our Automatic Welt Pocket Machine Transforms Your Garment Factory

Our mold-free Automatic Welt Pocket Machine is more than just an innovative piece of industrial sewing equipment—it’s a strategic investment that delivers tangible benefits to your garment factory, helping you save money, increase efficiency, and improve the quality of your products. Below are the key advantages that set our machine apart from any other industrial sewing machine on the market:

- Zero Mold Costs, Significant Savings

One of the most significant benefits of our mold-free design is the elimination of mold-related costs. Traditional Automatic Welt Pocket Machines require garment factories to purchase dozens, if not hundreds, of molds to accommodate different pocket sizes and designs. Each mold can cost hundreds of dollars, and over time, the cost of mold inventory, maintenance, and replacement adds up to a substantial financial burden. With our mold-free Fully Automatic Pocket Opening Machine, you can eliminate these costs entirely. There’s no need to purchase, store, or maintain molds—saving your garment factory thousands of dollars in operational costs each year.

For example, a mid-sized garment factory that produces 10 different pocket sizes might spend $5,000 or more on molds annually. With our machine, that $5,000 is redirected to other critical areas of your business—such as marketing, R&D, or expanding your product line. Additionally, our machine reduces waste, as there’s no need to discard old or damaged molds, making it a more sustainable choice for environmentally conscious garment factories.

2. Reduced Downtime, Increased Productivity

Downtime is the enemy of productivity in any garment factory. Traditional industrial sewing machines for pocket production require 30 minutes or more of downtime per mold change, which can add up to hours of lost production each week—especially for factories handling small-batch, custom orders. Our mold-free design eliminates this downtime entirely. With the ability to switch between pocket sizes in seconds, your machine can run continuously, maximizing productivity and ensuring you meet even the tightest deadlines.

Our Automatic Welt Pocket Machine also boasts an impressive sewing speed, capable of producing up to 3,000 stitches per minute—comparable to the fastest industrial sewing machines on the market—but with the added advantage of zero downtime for mold changes. This means your garment factory can produce more pockets in less time, increasing your output and revenue potential. For example, a garment factory that previously produced 1,000 pockets per day with a traditional machine can now produce 1,500 or more pockets per day with our mold-free machine, a 50% increase in productivity.

The efficiency gains are even more significant for factories handling custom orders or frequent size changes. With our machine, you can easily switch between different pocket sizes for different clients or orders, without sacrificing speed or precision. This flexibility allows you to take on more small-batch orders, expand your customer base, and stay competitive in a market that demands agility.

3. Unparalleled Precision and Consistency

In the fashion and textile industry, quality is everything. A poorly made pocket—with uneven stitching, incorrect dimensions, or misaligned edges—can ruin an entire garment, leading to wasted materials, lost revenue, and damage to your brand reputation. Our Automatic Welt Pocket Machine is designed to deliver unmatched precision and consistency, ensuring every pocket you produce meets the highest quality standards.

The motor-controlled adjustable mechanism uses high-precision sensors and advanced software to ensure that every pocket is cut and sewn to the exact dimensions you input. Unlike traditional mold-based machines, which can suffer from mold wear, misalignment, or human error during mold changes, our machine maintains consistent precision across every pocket—whether you’re producing 10 pockets or 10,000. This means fewer defects, less waste, and higher customer satisfaction.

Our automatic laser pocket welting machine takes this precision to the next level, leveraging laser technology to cut and welt pockets with microscopic accuracy. The laser ensures clean, smooth edges, eliminating fraying and ensuring a professional finish—perfect for high-end fashion brands and garments that demand attention to detail. Whether you’re producing simple welt pockets, automatic welt pocket with zipper, or complex back pockets for jeans, our machines deliver consistent, high-quality results every time.

4. User-Friendly Design, Minimal Training Required

We understand that not every garment factory has access to highly skilled operators, which is why we’ve designed our Automatic Welt Pocket Machine to be intuitive and easy to use. The machine features a large, touchscreen interface with clear, simple controls, allowing operators to input pocket dimensions, adjust settings, and monitor production with just a few taps. Even operators with no prior experience with industrial sewing machines can learn to use our machine in less than an hour.

The mold-free design also reduces the skill level required to operate the machine, as there’s no need for operators to learn how to change, install, or calibrate molds. This eliminates the need for costly training programs and reduces the risk of human error, ensuring consistent production even with a rotating workforce. Additionally, the machine features built-in safety features, including emergency stop buttons, safety guards, and automatic error detection, ensuring a safe working environment for your operators.

5. Versatility for All Fashion and Textile Applications

The fashion and textile industry is diverse, with a wide range of garment types, fabrics, and pocket designs. Our Automatic Welt Pocket Machine is designed to be versatile, capable of handling any pocket-making application—from lightweight fabrics like chiffon to heavy materials like denim and leather. The machine can produce a wide range of pocket types, including:

- Welt pockets (standard and custom sizes) with our Automatic Welt Pocket Machine

- Zippered pockets with our automatic welt pocket with zipper attachment

- Back pockets for jeans and casual wear with our specialized back pocket machine

- Laser-cut pockets with our automatic laser pocket welting machine

- Custom-sized pockets for children’s clothing, outerwear, bags, and more

This versatility makes our machine an ideal investment for any garment factory, regardless of its focus. Whether you specialize in high-end fashion, casual wear, workwear, or children’s clothing, our Fully Automatic Pocket Opening Machine can adapt to your needs, eliminating the need to purchase multiple industrial sewing machines for different applications.

6. Energy Efficiency, Reduced Operational Costs

In addition to eliminating mold costs and reducing downtime, our Automatic Welt Pocket Machine is designed to be energy-efficient, helping you reduce your garment factory’s energy bills and environmental footprint. The machine uses advanced motor technology that consumes less energy than traditional industrial sewing machines, without sacrificing performance. For example, our machine consumes up to 12% less energy than comparable models, translating to significant savings on your monthly energy costs.

The machine also features an automatic standby mode, which activates when the machine is not in use, further reducing energy consumption. Additionally, the mold-free design reduces waste, as there’s no need to discard old molds or materials damaged during mold changes—making it a more sustainable choice for garment factories looking to reduce their environmental impact.

Why Choose Our Industrial Sewing Machines for Your Garment Factory?

In a market flooded with industrial sewing machine manufacturers, what sets us apart? For six years, we have remained committed to one core principle: putting our clients’ needs first. We don’t just sell machines—we deliver solutions that help garment factories thrive in a competitive market. Here are the reasons why garment factories worldwide choose our Automatic Welt Pocket Machine, Fully Automatic Pocket Opening Machine, and other garment equipment:

1. Proven Expertise and Experience

Six years of focused R&D and innovation have made us experts in automatic pocket-making technology. Our team has a deep understanding of the fashion and textile industry, and we use this knowledge to design machines that address the real pain points of garment factories. We don’t cut corners—every machine is built to the highest standards of quality and durability, ensuring it will serve your factory for years to come.

Our track record speaks for itself. We have supplied our Automatic Welt Pocket Machine, back pocket machine, and automatic laser pocket welting machine to hundreds of garment factories worldwide, helping them reduce costs, increase productivity, and improve quality. Our clients include small family-owned factories, mid-sized manufacturers, and large-scale production facilities—all of whom trust us to deliver reliable, high-performance industrial sewing machines.

2. Revolutionary Innovation

We are not content to follow industry trends—we set them. Our mold-free Fully Automatic Pocket Opening Machine is the latest example of our commitment to innovation, offering a solution that no other manufacturer can match. We invest heavily in R&D, ensuring we stay ahead of the curve and continue to deliver cutting-edge technology that helps our clients stay competitive.

We also listen to our clients, using their feedback to drive innovation. Every improvement we make to our Automatic Welt Pocket Machine, every new feature we add, is based on the real needs of garment factory owners and operators. This client-centric approach ensures our machines are not just innovative, but practical and useful—designed to solve the problems that matter most to you

3. Uncompromising Quality

Quality is at the heart of everything we do. Every component of our industrial sewing machines is carefully selected for its durability and performance, and every machine undergoes rigorous testing before it leaves our factory. We use only the highest-quality materials, including premium motors, precision sensors, and durable sewing mechanisms, ensuring our machines can withstand the demands of 24/7 production in a busy garment factory.

We also offer a comprehensive warranty on all our machines, giving you peace of mind knowing that your investment is protected. Our warranty covers all parts and labor for a minimum of 12 months, and we offer extended warranty options for additional protection. Additionally, we have a global network of service centers and technicians, ensuring you can get the support you need, no matter where your factory is located.

4. Global Support and Service

We understand the importance of reliable support and service for our global clients. We have built a comprehensive global support network, with service centers and technicians in key regions around the world, including Europe, Asia, Africa, and the Americas. Our technicians are highly trained and experienced, capable of diagnosing and resolving any issues with your Automatic Welt Pocket Machine, back pocket machine, or automatic laser pocket welting machine quickly and efficiently.

We also offer 20/7 technical support via phone, email, and video call, ensuring you can get help whenever you need it—even outside of regular business hours. Additionally, we provide training programs for your operators, either on-site or via video, to ensure they have the skills and knowledge to use our machines to their full potential. We also supply genuine replacement parts, ensuring your machine remains in top condition and minimizing downtime in the event of a breakdown.

5. Competitive Pricing and Flexible Payment Terms

We believe that innovative, high-quality industrial sewing machines should be accessible to garment factories of all sizes. That’s why we offer competitive pricing on all our machines, including the mold-free Fully Automatic Pocket Opening Machine, Automatic Welt Pocket Machine, and automatic welt pocket with zipper. We also offer flexible payment terms, including installment plans and trade-in options for your old machines, making it easier for you to invest in the technology that will transform your production.

Additionally, we offer bulk discounts for large orders, making our machines an even more cost-effective choice for large-scale garment factories. Our goal is to help you reduce your operational costs, not increase them—so we work hard to ensure our pricing is fair, transparent, and competitive.

Transforming the Future of Fashion and Textile Manufacturing

The fashion and textile industry is changing rapidly, and garment factories that fail to adapt will be left behind. Consumers are demanding more customization, faster delivery times, and higher quality products—all while expecting lower prices. To meet these demands, garment factories need industrial sewing machine solutions that are efficient, versatile, and innovative.

Our mold-free Fully Automatic Pocket Opening Machine is more than just a piece of equipment—it’s a catalyst for change. It eliminates the biggest pain points of pocket production, reduces costs, increases productivity, and delivers unmatched quality, helping your garment factory stay ahead in a competitive market. Whether you’re a small factory looking to expand your capabilities or a large manufacturer looking to optimize your production line, our Automatic Welt Pocket Machine is the solution you’ve been waiting for.

Over the past six years, we have grown from a small R&D team to a global leader in automatic sewing equipment, and we’re just getting started. We will continue to invest in R&D, innovate, and improve our products, ensuring we remain at the forefront of the industry. Our commitment to our clients is unwavering: we will deliver the best industrial sewing machine solutions, the most reliable support, and the most competitive pricing, helping you succeed in the dynamic world of fashion and textile manufacturing.

Contact Us Today to Revolutionize Your Garment Factory Production

Are you ready to eliminate mold costs, reduce downtime, and boost productivity with the world’s first mold-free Automatic Welt Pocket Machine? Contact us today to learn more about our revolutionary Fully Automatic Pocket Opening Machine, automatic laser pocket welting machine, back pocket machine, automatic welt pocket with zipper, and other industrial sewing machine solutions.

Our team of experts will work with you to understand your garment factory’s unique needs, answer any questions you may have, and provide a customized solution that fits your budget and production goals. We offer free demonstrations, so you can see our machines in action and experience the difference for yourself. We also provide fast, reliable shipping to any country in the world, ensuring you get your machine as quickly as possible.

Join the hundreds of garment factories worldwide that have transformed their production with our innovative industrial sewing machines. Together, we can redefine the future of fashion and textile manufacturing—one pocket at a time.

Post time: Feb-09-2026