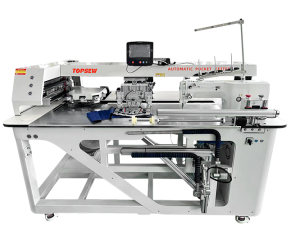

Automatic Coverstitch Bottom Hemmer TS-800

1. High efficiency: 220-250 pcs/hour. One person can operate 2-3 machines. It can save 3-5 workmen.

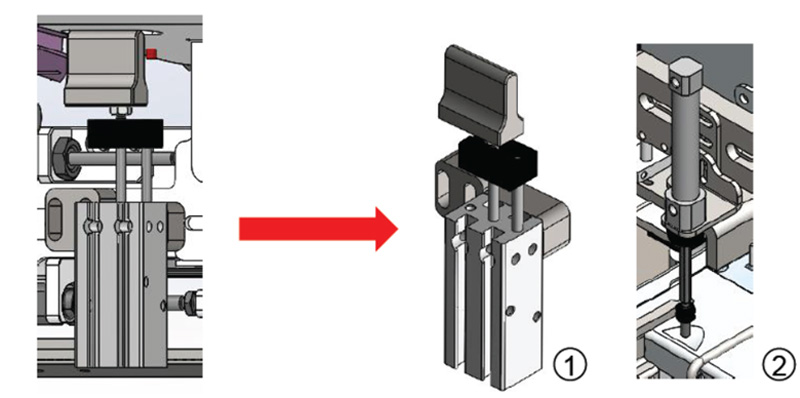

2. Fully automatic: automatic trimming, automatic size control, automatic fabric guide and folding, automatic material collection.

3. It is easy to operate, no technical requirements for workers.

4. The quality of each piece sewed out is perfect.

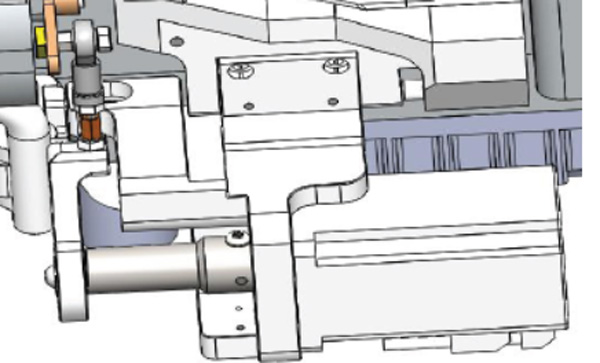

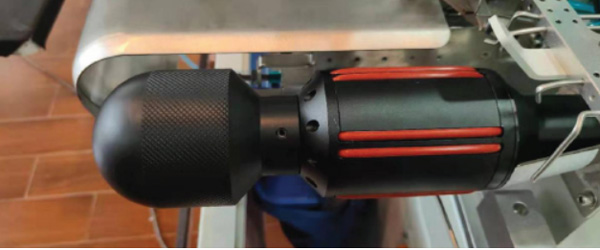

5. It makes the knitting T-shirt type hem process can be completed in a single sewing. This machine is equipped with two needle three-wire or three needle five-wire stretch sewing machine. It is a necessary machine for knitting garment enterprises.

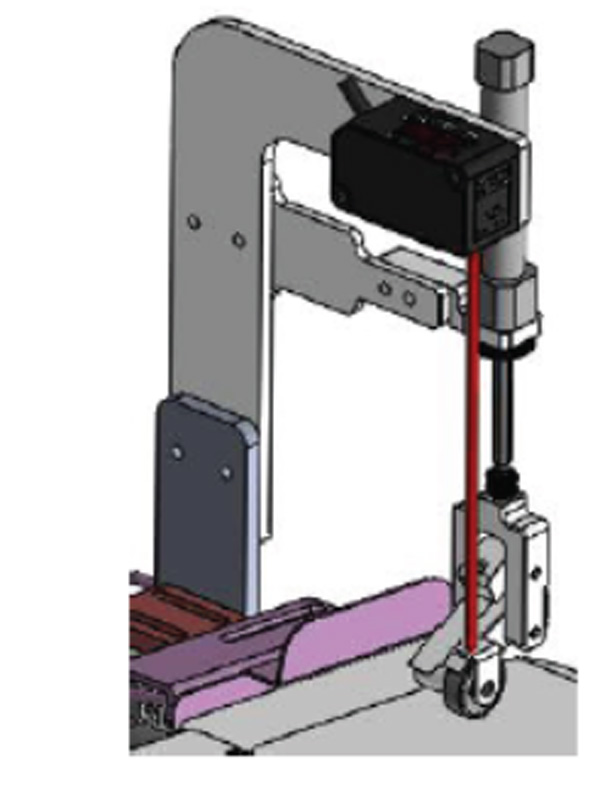

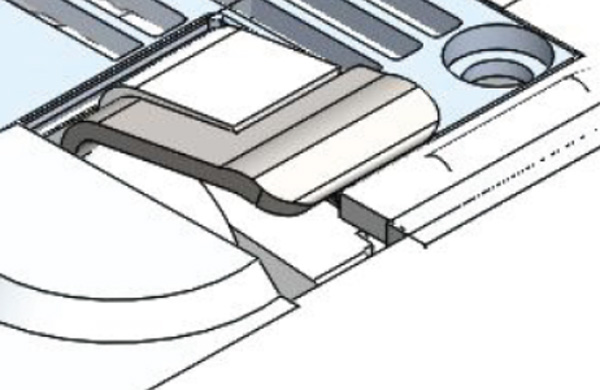

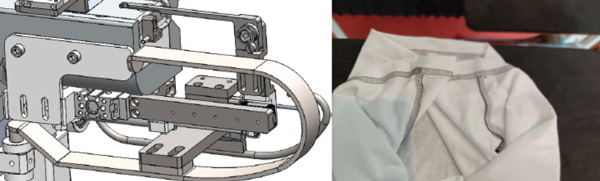

The tubular or side seam cloth is placed on the expansion rollers, and the rollers automatically adjust the appropriate tension. After guiding the sewing cloth to the presser foot, the sewing button is started, the starting and ending stitches are completely aligned, and the products are stacked automatically after automatic cutting.

Automatic Coverstitch Bottom Hemming Machine is suitable for automatic hem sewing, knit round T-shirt, POLO shirt, thermal underwear, etc.

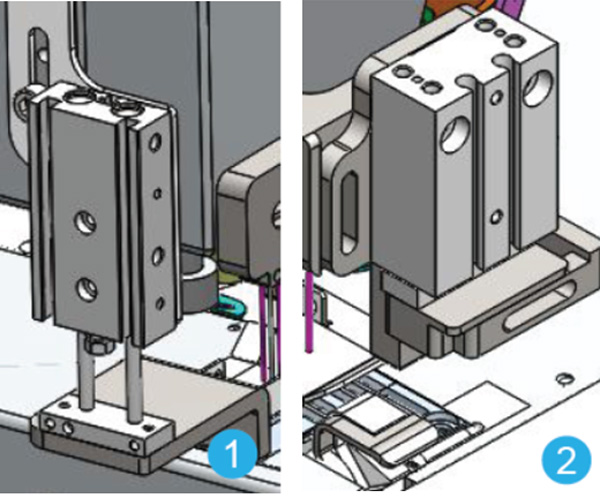

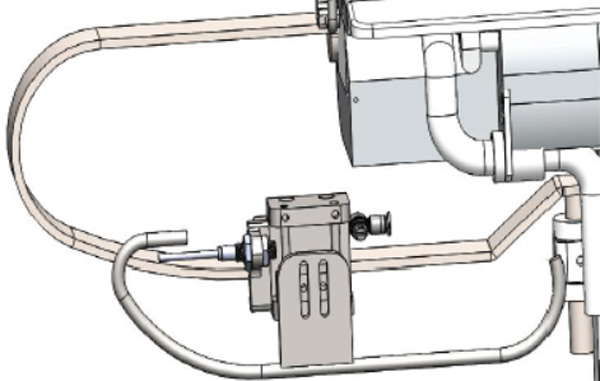

The latest automatic bottom hemmer can ensure the same seam directions(inside and outside )are well aligned and assist andensure the stability of overflipping real seam direction,avoid error detecting on fabric colour, improve the speedand stability,the knife can be changed easily and fast,realize the expension and identification the sizeautomatically,achieve a real seam direction overflipping, automatic bottom hemmer adopts two rectifying belts in each group to enhance the stability of the rectifying deviation effects.

| Model | TS-800 |

| production capcity | 200-250 pcs per hour |

| Sewing head model | PEGASUS:W3662P-35B |

| Voltage | 220v |

| Current | 6.5A |

| Air pressure | 6KG |

| Size range | Stretchable diameter rang available 38cm-82cm, Hem width 1.3cm-3.5cm |

| Gas consumption | 200L/min |

| Power | 1100W |

| Head speed | 4000RPM |

| Wеіght (N.W) | 241kg |

| Dimension(N.S) | 135*100*150cm |